March 8, 2017 Venue Report (Part 2)

Not only large companies from the metro area but also overseas and local small and medium-sized companies participated in the JAPAN SHOP 2017. Let me introduce some of the booths that reflect their regional characteristics and cultural background strongly in manufacturing.

Reported by Hisashi Ikai

01.Koyoseiga (Hyogo prefecture) [NIPPON MONO ICHI]

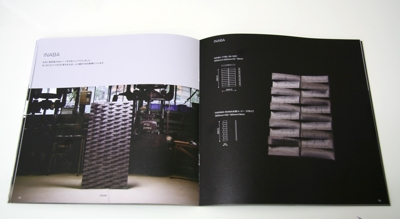

Funatsu-cho, Himeji city, where tile making has been taking place for a long time since various quality clays are dug out. Each roof tile made by Koyoseiga, which was founded in Taisho 12, has slightly different expressions one by one. Aiming for robust manufacturing with high durability, the time for sintering is about twice as much, compared to the ordinary tiles. By continuing firing for four days, the "Ibushi Tile" with an austere silver finish is completed.

The high functionality and expression of this Ibushi tile used also in the Himeji Castle has become a topic; in recent years it developed wall and flooring materials in addition to its traditional type. Last year, designer Yukitoshi Toda joined as director and produced a new catalog. Photos of impressive works from the factory are introduced with their actual products.

Another characteristic of the Koyoseiga, is not only its manufacture but also its system to consistently undertake from tiling, management, and maintenance. "We may be asked to repair again after 50 years. Like a primary doctor, we keep on watching all the time from their birth," says Natsuko Sasada, the representative.

02.Fuji Paper Mills Cooperative (Tokushima prefecture) [NIPPON MONO ICHI]

Japanese traditional paper "Awa Washi" which remains in the area centered on Yoshinogawa city, Tokushima prefecture. Traditional Japanese paper boasting a history of more than 1300 years, tags with another traditional industry that is communicated to the region, pursuing the value of new manufacturing.

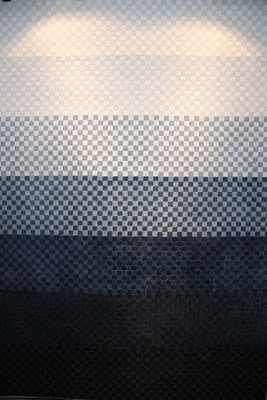

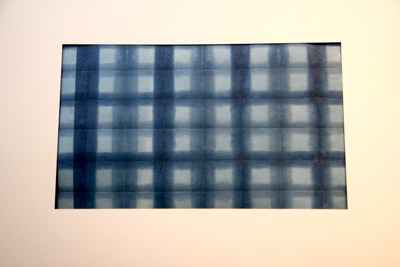

Speaking of Tokushima prefecture along with Awa Washi, is a raw material resource that becomes an indigo color called "sukumo". The production of sukumo, which reached its peak in the Edo era, gradually decreased its production volume in accordance with the influx of Western culture and the change in lifestyle as well as Japanese paper. However, in recent years, with the help of the movement to review unique Japanese manufacturing, Awagami Factory operated by Fuji Paper Mills has made full-fledged production of "Aizome Washi" that combines two local industries and is able to constantly supply a certain amount.

The dyeing work of indigo dye paper is handled by Mieko Fujimori of Fuji Paper Mills. Dyeing by soaking in water many times is not compatible with paper usually, but by applying konjac paste on washi paper makes it stronger. A material with a new expression matched with the texture and the beautiful indigo gradated washi paper was completed.

Even based on its traditional process method, it also supports inkjet printing. She says she wants to propose a wide range of applications so that it becomes a properly suited material for modern manufacturing.

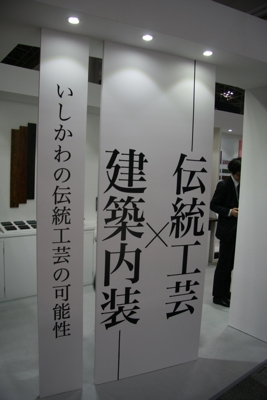

03.Ishikawa Prefecture

The Kaga clan was opened by Toshiie Maeda, which was extremely prosper in the Edo era, many art and craft skills were born and consolidated in the territory. Among that exist in the present, craftsmen who boast the technical skills announced projects to challenge and apply in the interior building materials at JAPAN SHOP.

Taya Shikkiten of Wajima coating proposed the pillar and floor of the house to be lacquered. Although it seemed to be surprising, in Noto district the method is commonly used for a long time, and is clearly said to be different in touch, durability, and increase in water resistance.

Meanwhile, Okuda Senshoku, which continues to make a beautiful patterned design "Kaga Yuzen", announced a project with a tag with the American interior brand, "MOQU". In the asymmetrically assembled box, the panel of Kaga Yuzen shined as an accent.

In addition, seven companies from five fields representing Ishikawa such as gilding, wood lathes and Japanese washi, were making a challenging proposal.

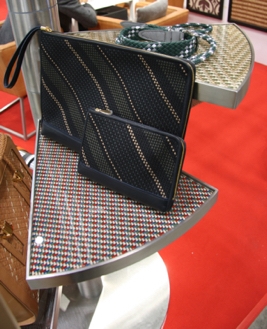

04.MANIFATTURA DI DOMODOSSOLA

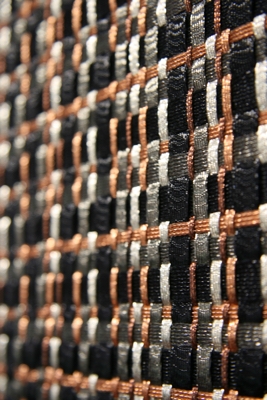

Manifattura di Domodossola, headquartered in Domodossola, in the northern part of Italy. Founded in 1913, has been continuously producing since its establishment is a mesh used for belts, bags, and shoes straps. Of course with leather, but also specializing to knit all kinds of materials such as metal and cork, and too hard to tell if anyone from fashion industry doesn't know the company, has been focusing on collaborating with the interior industry in recent years.

Since the fact adding mesh material increases the products' luxurious feeling, orders are coming from all sorts, from luxury hotel rooms and receptions, to concept car interior, etc.

"We do sell art panels alone, but with interior designers and architects with rich ideas, we look forward to challenge in various expressions", said the spokesman. They will launch a new interior brand "OXILLA" and expand further development.